From Style to Distribution: Mastering the Art of T-Shirt Screen Printing

The trip from layout to distribution in t-shirt screen printing encompasses a series of important phases that require focus to information and strategic planning. It begins with comprehending the nuances of your target audience, adhered to by the selection of suitable materials and the preparation of artwork that satisfies high requirements. As the process unfolds, challenges in quality control and logistics can arise, potentially impacting the final outcome. Exploring these complexities discloses not just the details of screen printing yet additionally the crucial techniques that can boost a brand name's standing in a competitive market.

Comprehending T-Shirt Screen Printing

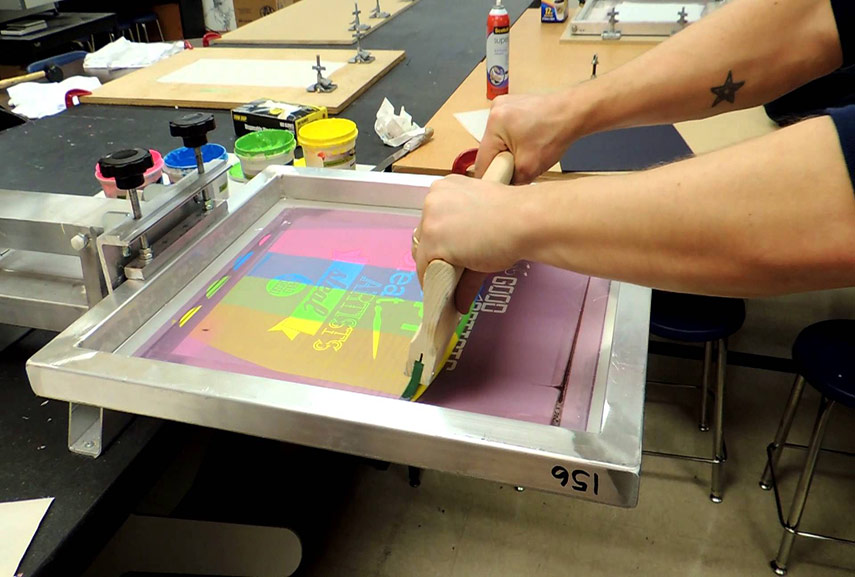

Understanding T-Shirt screen printing involves identifying a functional and commonly utilized method for transferring layouts onto material. This method utilizes a mesh and a pattern screen to use ink onto different textile products, generally cotton and polyester blends. The process starts with the production of a screen that features the wanted style, which is then carefully straightened on the material.

Ink is pushed via the screen's open locations using a squeegee, permitting exact application of color. This approach is favored for its ability to generate dynamic, long-lasting prints that stand up well to washing and put on. Furthermore, screen printing is capable of suiting both basic and complex layouts, making it a recommended option for custom-made clothing, advertising products, and also artistic jobs.

Screen printing uses scalability, making it suitable for both little batch orders and large-scale manufacturings. While first configuration prices may be higher contrasted to various other printing methods, the efficiency and toughness of screen printing frequently warrant the investment. In general, recognizing the principles of T-shirt screen printing is necessary for anyone wanting to participate in this preferred form of material decor, whether for personal jobs or industrial undertakings.

Conceiving Your Design

Conceptualizing your style is a crucial action in the T-shirt screen printing process, as it sets the foundation for the entire job. This stage entails creating concepts that resonate with your target audience while ensuring that the style lines up with the brand name's identification and message. It is necessary to start by exploring themes, color pattern, and graphics that reflect the intended aesthetic.

Mapping out preliminary ideas can be useful, enabling a graph of concepts before finalizing the style (Screen Printing). Think about the usage of typography, images, and design in such a way that catches interest and interacts successfully. Additionally, it is essential to anticipate the printing technique that will certainly be used, as this can affect style intricacy and shade selections

Taking part in conceptualizing sessions with team members or looking for comments from prospective customers can also enhance the concept process, offering diverse viewpoints that fine-tune the design. Inevitably, a well-balanced design not only enhances the aesthetic charm of the Tees yet likewise fosters a link with the audience, driving interest and possible sales. Dedicating time to conceive your design can lead to an effective screen printing result.

Selecting the Right Products

When selecting the ideal materials for Tees screen printing, it is necessary to take into account the textile's structure, weight, and appearance, as these variables significantly influence the final item's top quality and really feel. Cotton is a preferred option as a result of its softness, breathability, and capability to absorb ink successfully, making it suitable for vibrant prints - T-Shirt Printing. Blends, such as cotton-polyester, deal resilience and crease resistance, yet might affect ink adherence, calling for cautious factor to consider of printing techniques

The weight of the fabric, usually gauged in grams per square meter (GSM), affects the drape and overall feel of the T-shirt. Much heavier materials might give a more premium appearance, while lighter options are comfortable for sportswear. Appearance additionally contributes; smoother fabrics tend to yield sharper prints, while textured surfaces can create distinct aesthetic results.

Furthermore, think about the environmental impact of products. Organic cotton and recycled polyester are gaining popularity amongst eco-conscious customers. Inevitably, picking the best products includes balancing aesthetic appeal, functionality, and sustainability, ensuring that the Tees not just looks wonderful yet likewise satisfies the expectations of your target audience.

Preparing Art Work for Printing

Preparing artwork for T-shirt screen printing calls for cautious attention to information to ensure that the last print precisely shows the intended layout. The very first step is to develop a high-resolution digital documents, ideally in vector layout, as this enables for scalability without loss of quality. Usual software application used for this function includes Adobe Illustrator and CorelDRAW.

Take into consideration the measurements of the print location and keep appropriate margins to prevent style cutoff. It's also smart to consist of enrollment marks for placement throughout the printing process. Lastly, request an evidence from the printer to picture the end product before automation. This action is crucial for recognizing any type of prospective issues, assuring that the published T-shirt fulfills the preferred top quality and style requirements. Appropriate prep work of artwork greatly affects the general success of the screen printing task.

Understanding the Printing Process

Next off, picking the appropriate ink is necessary. Different ink types, such as plastisol or water-based, offer various finishes and longevity. Comprehending the fabric composition of the Tee shirts likewise aids in picking suitable inks.

When it involves the real printing, managing the squeegee pressure and angle is essential. Constant pressure will generate also ink distribution, while the angle affects the circulation and insurance coverage. In addition, readjusting the rate of the printing press can impact the ink's healing procedure, which is fundamental for assuring longevity.

Quality Assurance and Finishing

After the printing process is complete, implementing reliable quality assurance steps becomes crucial to confirm that each Tees satisfies the desired standards. Quality assurance includes a systematic technique to examining each garment for defects, verifying that the print quality, shade accuracy, and material stability align with the specs set throughout the design phase.

The primary step in top quality control is a complete visual assessment. This entails monitoring for common problems such as imbalance, ink smudges, or fading. Any kind of T-shirt that does not satisfy the top quality criteria need to be resolved quickly, either via reprinting or repair service.

In addition to visual checks, it is necessary to carry out clean tests on an example of printed tee shirts to assess the toughness of the inks and the overall durability of the design. These tests assist verify that the print will certainly maintain its vibrancy and stability after several cleans, an important aspect for consumer complete satisfaction.

Ending up touches, such as thread trimming and the application of care labels, likewise play a substantial duty in quality assurance. By focusing on these elements, services can boost the total presentation of their products, ultimately resulting in a much more gratifying consumer experience.

Product Packaging and Distribution Solutions

Reliable product packaging and delivery solutions are essential elements of the Tee shirts screen printing process, as they guarantee that garments show up at their destination in beautiful problem. Appropriate product packaging not just shields the published styles however likewise improves the unboxing experience for customers, reinforcing brand identity and professionalism and reliability.

To accomplish optimal packaging, consider using eco-friendly products that straighten with sustainability patterns, such as recyclable poly bags or naturally degradable boxes. Each Tees need to be nicely folded and placed in safety covering to stop creasing and potential damages during transit. Including a well-known insert or care instructions can better individualize the experience, promoting customer commitment.

Picking a trustworthy shipping companion is vital when it comes to delivery. Review choices based on expense, monitoring, and speed abilities. Offering several delivery methods can accommodate different client needs, from common to expedited shipping.

Often Asked Inquiries

What Are the Typical Blunders Beginners Make in Screen Printing?

Usual mistakes novices make in screen printing consist of improper screen prep work, poor ink mixing, inaccurate direct exposure times, insufficient treating, and neglecting to check prints. These mistakes can lead to low quality and unsuitable outcomes in end products.

Exactly How Can I Stop Ink From Bleeding During Printing?

To stop ink blood loss why not look here throughout printing, guarantee appropriate screen tension, usage ideal solution thickness, select the ideal ink uniformity, keep ideal curing temperatures, and prevent overwhelming the screen with too much ink throughout application.

What Kinds of Inks Are Ideal for Different Fabrics?

Selecting inks based on fabric type is vital. Water-based inks are suitable for cotton, giving soft qualities. Plastisol inks suit artificial textiles, offering toughness (Abilene T-Shirt Screen Printing Company). Discharge inks effectively blend with all-natural fibers, making certain vivid shades without jeopardizing material honesty

Just how Do I Select the Right Screen Mesh Count?

Choosing the right screen mesh matter relies on the preferred print detail and ink kind. Greater mesh counts yield finer information, while lower counts facilitate thicker inks. Analyze material type and design intricacy for optimal results.

Can I Use Screen Printing for Tiny Batch Orders?

Yes, screen printing can be effectively made use of for little batch orders. 10:9 Design Business Branding Solutions. This method enables top notch results and thorough styles, making it a feasible option for custom-made clothing, advertising things, or limited edition runs

Comprehending T-Shirt screen printing entails acknowledging a functional and extensively utilized approach for transferring layouts onto fabric. While initial setup costs may be higher compared to various other printing methods, the performance and sturdiness of screen printing often validate the financial investment. Preparing artwork for T-shirt screen printing calls for cautious focus to detail to ensure that the last print properly reflects the designated layout. Mastering the printing process is essential for accomplishing high-quality results in Tee shirts screen printing. Typical blunders newbies make in screen printing include incorrect screen preparation, insufficient ink blending, wrong exposure times, insufficient healing, and neglecting to evaluate prints.